Honing angles, grinding angles, cutting angles, angles of attack, frog angles, primary bevel angles, secondary bevel angles, micro bevels, back bevels………….. Confused? You should be!

But don’t let yourself get distracted by technical terminology, you’ll be pleased to hear that it’s all remarkably simple really – for a chisel you just need to understand Bevel Angles, for a plane, you need Bevel Angles and Cutting Angles, so there you are, not complicated at all.

BEVEL ANGLES & STEEL

First, just consider what the blade is made from, if you think that metallurgy might be your thing and you want to know your Molybdenum from your Chromium Carbides, have a look at Ron Hock’s website http://www.hocktools.com/tech-info/o1-vs-a2.html for an excellent explanation on all things relating to steel for blades.

However, if you don’t fancy getting all technical, all you really need to know is that blades made from harder steel (e.g. A2) might need sharpening less frequently BUT, ironically, the harder the steel, the more brittle and fragile the cutting edge.

Conversely, a ‘softer’ steel (e.g. O1) when freshly sharpened will usually be ‘sharper’ and less brittle but might need sharpening more frequently.

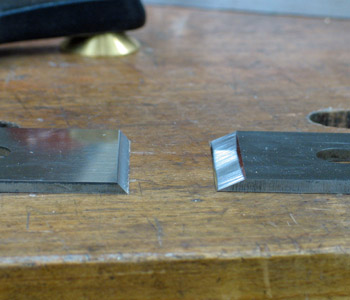

Harder steels producing a fragile cutting edge need a higher bevel angle to give a bit of support.

Which steel do I use? Generally I’m drawn towards ‘O1’ High Carbon steel because I feel you can get a sharper edge and I sharpen frequently anyway, but I use both.

BEVEL ANGLES & ACTIVITY

What is the blade being used for? Gentle paring is a far less traumatic activity for a blade than chopping out mortices. So, a lower bevel angle for paring, higher for being welted with a big mallet. Ultimately, choose a bevel angle, try it, if the edge disintegrates quickly, increase the angle a bit and try again.

Greater trauma requires a greater bevel angle

BEVEL ANGLES & CUTTING ANGLES

The ‘Cutting Angle’ or ‘Angle of Attack’ is relevant when a blade is installed in a plane and affects the way a plane works. It’s the angle between the surface of the thing being planed and the top surface of the blade. The critical thing to think of here is whether the blade is installed in the plane ‘Bevel Up’ or ‘Bevel Down’.

A standard Bench Plane will be ‘Bevel Down’ and the blade will be fitted with a ‘chip breaker’. In this case the cutting angle will be the same as the ‘Frog Angle’.

Why a ‘Frog’? Have a look at this http://www.finewoodworking.com/item/38319/just-plane-trivia-why-do-they-call-it-a-frog who knows, it might even be true!

Cutting Angle is controlled by the Frog on a ‘Bevel Down’ plane, not the Bevel.

A Block Plane and other ‘low angle’ planes will be ‘Bevel Up’. The blade sits on the plane’s bed and the ‘Cutting Angle’ is a combination of the ‘bed angle’ and the ‘bevel angle’

On a ‘Bevel Up’ plane, the Bevel Angle controls the Cutting Angle.

What about all those other angles? Sometimes they’re just different names for the same thing. A ‘Secondary Bevel’ is actually the same as the ‘Bevel Angle’ that I’ve been talking about and only becomes relevant if you’re using a honing guide, a ‘Micro Bevel’ is a degree or so higher than a Secondary Bevel and again it’s a honing guide thing. A ‘Back Bevel’ is pretty much what it says it is, it’s a small bevel on the back of a blade, this can be used to increase the ‘Cutting Angle’ by a few degrees on a Bevel Down plane. For some people a ‘Back Bevel’ is a rather controversial concept.

Although I feel it’s important that you have an understanding of steels and angles, the bottom line is that at some point you’re going to have to come to terms with the unpleasant fact that sharpening is something that has to be done pretty frequently, regardless of how exotic your blade material is. When you have good quality blades and you have finally succumbed to this vital principle, the quality of your woodwork will make a quantum leap.

…… A little bit of Homework for you this month – What, if anything, happens to the Cutting Angle if a plane is skewed as it is pushed forwards to take a shaving?