My very first car, a Ford Consul Classic, had twin headlights, they were one of its most alluring features, that and the front bench seat and column gear-change. No one with any vague sort of aspirations to becoming a ‘boy racer’ would ever pass up on a set of twin headlights would they? Quite apart from their ability to light the road ahead with twice the brightness of a single pair of headlights, which 40 years ago with rather dim bulbs was quite a desirable feature, twin headlights always look great, just think of the original Golf GTI!! The problem with my first car was that despite its very glamorous headlight arrangement, the rest of it was an absolute disaster – the doors didn’t close properly (only partly due to reversing into a large post outside a pub), the starter-motor kept jamming, the wheel-arches were full of rust, the windscreen wipers had to be manually assisted……………………………….in fact ‘disaster’ is probably being overly kind.

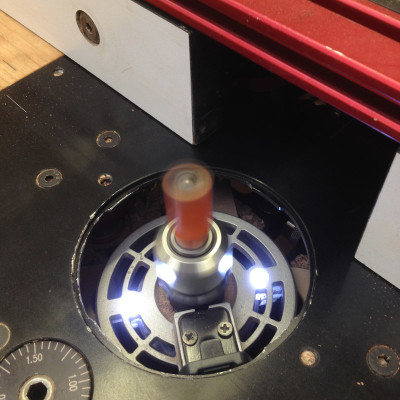

This little trip down memory lane was brought about by the arrival of my latest router, complete with its very own has twin LED headlights, not that they’re going to be of very much benefit to me as this German machine, in its rather fetching orange and silver livery, is destined for a life of being dangled upside down in a router table. But I have high hopes for this new router, quite apart from the sexy headlights, it seems nicely made, has two different bases and all sorts of other useful looking bits and bobs, it even arrived with its own stylish orange holdall.

The reason for a new router? Well, I’ve been having a battle with my router table for some time now. It’s become something of a love / hate relationship over the last few years which has developed into a bit of a war of attrition and has resulted in, at the last count, seven dead, or dying, routers. You might think, ‘how difficult can it be to make a router table?’ Well it turns out it’s quite a tricky thing to pull off. The challenges start because most routers are not actually designed to be used upside down, as soon as you do this you are creating a whole host of potential problems, from the challenge of accurate height adjustment to the nightmare of changing blades on a machine that’s being held the wrong way up in a confined space that’s poorly lit. A scenario that generally results in much cursing and shredded knuckles. At one time I thought the Triton router was the answer, it’s certainly designed with the router table in mind, but the electronics turned out to be rather puny and after three trips to the repair man we decided to part company. We discovered some cunning fittings, like the “Router Raizer” for making height adjustment a breeze, but it kept falling apart, the “Xtreme Xtension” made changing blades a doddle, but the adjusting screw proved to be rather fragile and ultimately this fitting, with its extra length, managed to kill the router it was fitted to. A few months ago I decided that enough was enough, we needed to get serious about this problem and throw some real money at it. I came across a beautifully made Canadian lift that could be paired with a purpose made motor from China. What could possibly go wrong? Well, the motors! Once again, the electronics turned out to be their Achilles’ heel and a couple of months later 4 motors had been packaged up and returned.

So we found ourselves with a choice of one router that has the correct voltage, is available in Europe, and fits into the Canadian lift. Thankfully that router is an ‘AEG’, it must be good quality, it’s German, this has just got to be the solution that we’ve spent so many years searching for, and it’s even fitted with twin headlights!

Upon close inspection, I have found that my new ‘German’ router is stamped with the words ‘Made in the PRC’. But some things that are produced in the People’s Republic of China are made really well ……………………………………..aren’t they??

© 2025 · John Lloyd Furniture & John Lloyd Furniture School